Hole scanning |

|

|

|

Hole scanning |

|

|

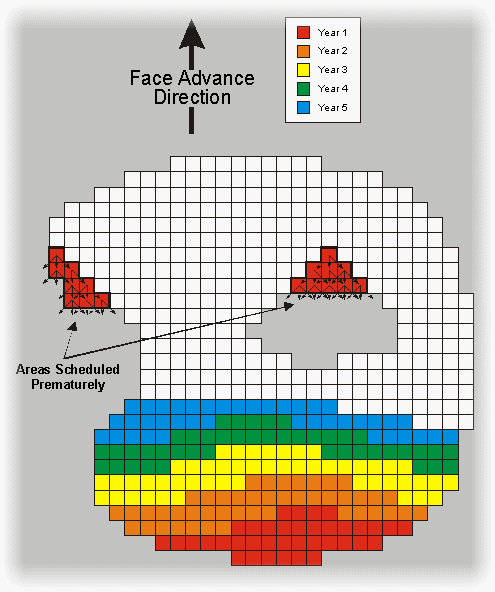

When absolute bearing and relative bearing rule sets are used, the dependencies they create are omitted from the project if the predecessor record does not exist in the database. Although in most situations this is the appropriate response to the missing block, it can cause unwanted behaviour in certain situations.

Where topography intersects the upper benches of a project, holes can occur in the effected benches. If all the predecessors of blocks around the hole are missing, they will not be assigned dependencies and will therefore be treated as available blocks. Similar effects can also be seen around the edges of irregular shaped deposits.

When this situation occurs, the blocks are often scheduled too early, normally in V shaped areas in the lee of holes and to prevent this from occurring, specific rules must be defined for each area.

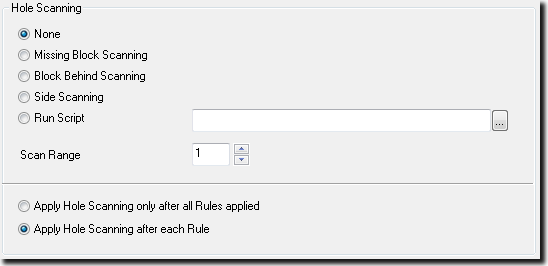

Hole scanning techniques are used to avoid the need for these specific rules. They function by iteratively applying the appropriate dependency rules to missing blocks until an record is found. A number of alternative methods have been provided to perform this function and these are assigned on the rule sets Circular Reference Checking tab.

Another valuable use for hole scanning occurs when records in the database do not necessarily have sequential APIL numbers and the next record in the database hierarchy should be used as the predecessor, rather than a record with a specific APIL. An example of this situation is in open strip coal mines, where seams can be missing due to geological factors or seam aggregation.

By default, hole scanning is not active and if required, the option button associated with one of the four scanning methods should be selected. Each method is different and their effectiveness varies in different circumstances.

| • | Missing Block Scanning is the simplest method and is the most commonly used. If a rules points to a predecessor that is missing, the rule will be re-applied but from the location of the missing predecessor rather than the successors location. The scanning process repeats until a block is found or the maximum number of iterations specified in the Scan Range text box is reached. If a block is not found during the scanning process, a dependency will not be created. |

| • | Block Behind Scanning takes a similar approach, but rather than applying the rule to the location of the missing block, it is applied to the block behind the successor, based on it's face advance direction. The scanning process continues to apply the rule to blocks further behind until a predecessor is located or the scan range is exceeded. |

| • | Side Scanning is quite different to the other methods and is more suited to large holes. If this technique is used and the desired predecessor record is missing, the AutoScheduler will scan from side to side, looking for an alternative predecessor. It first looks for the block behind and left, then behind and right. If neither of these exist, it will look for the block behind and two to the left, then behind and two to the right. This process will be repeated until a suitable predecessor is found or the scan range is exceeded. |

| • | The Run Script option is provided as an alternative when the pre-defined hole-scanning methods are not suitable. If this option is selected, a script will be executed whenever a missing block is encountered, allowing the user to evaluate the circumstances and take the most appropriate action. |

Two additional option buttons have been provided to further customise the behaviour of the hole scanning methods. By default, the Apply After Each Rule option is selected which causes hole scanning to be performed whenever a predecessor block is missing. But if the Apply Only After All Rules option is selected, no hole scanning will occur unless all of the rules in the rule set point to missing blocks.